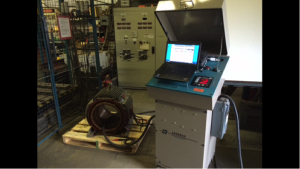

Bar to bar testing a DC armature.

The heart of an electric motor is its winding. Whether it is stationary or rotating we have the equipment to test your windings to ensure long trouble free operation. With our equipment we can perform; insulation resistance, high-potential, micro-ohm, high frequency bar to bar, and surge comparison testing of stators, armatures, pole pieces, coils etc.

Surge Comparison test of AC stators

The laminations and the insulation separating them in an electric motor can become damaged in many ways; Fusing of laminations during the release of energy caused by a short circuit, Overheating during winding removal, rotor / stator rubs caused by failing bearings or windings, or an excessive number of rewinds (winding removals) can cause the inter-laminar insulation to break down.

Damaged laminations can cause excessive heat; increase energy consumption, cause warps or bows, sparking brushes etc. These conditions that may hasten the next repair

AC Stator Core Test

Our Lexseco core tester is used to detect damaged laminations needing repair which may cause reliability issues, and excessive energy consumption. The Lexseco tester models the ideal core condition and compares the stator / armature test results, providing a report with recommendations. Records of core tests are kept on file for further comparison, and future recall.